17

Along with tracking ingredient levels and changes through testing, it is equally important to think about the order of ingredient addition and the function of each processing step.

Formulation Steps – Where to Start

Think through the processing steps to make a food. What is the function of each step? Does the order of the steps matter? To help answer these questions, think about what would happen if all of the ingredients were mixed together in one step. Need terminology to help describe the process? Check out the Common Processing Steps table below.

| Processing Method | Definition | Example(s) |

| Baked Products: | ||

| Creaming | Mixing fat and sugar together vigorously to create an air-in-fat foam | Shortened Cakes and Cookies |

| Beating | Very vigorous agitation of food mixtures using an electric mixer at high speed or a wooden spoon to trap air and/or develop gluten or an emulsion | Shortened Cakes, egg white foams like in Angel Food Cake |

| Stirring/moderate mixing | The gentle blending of ingredients when trapping of air and development of gluten are not necessary | Muffins, various quick breads |

| Folding | Very gentle manipulation used to bring batter up from the bottom of the mixing bowl while incorporating dry ingredients or another batter, all without releasing air from the foam | Angel food cake, soufflé, chiffon cake |

| Cutting In | Process of cutting solid fats (generally mixed with flour) into small pieces using a pastry blender | Biscuits and Pastry |

| Kneading | Folding over a ball of dough and pressing it with either the fingertips or the heels of both hands, depending upon the amount of gluten needing to be developed and the ratio of ingredients | Biscuits, Yeast Bread, Pizza Crust |

| Size Reduction: | ||

| Cutting/Chopping | Reducing the size of an ingredient to medium to small pieces | Fruits, Vegetables, Nuts |

| Grinding/Milling | Reducing the size of a typically dry ingredient to a very small piece or powder | Grains, Nuts |

| Processing or Blending | Reducing the size and mixing ingredients together, typically with a food processor or blender, to create a liquid or paste | Fruits, Vegetables, Juices, Nuts, Peanuts |

| Shaping: | ||

| Rolling/Laminating | Flattening a dough to a given thickness, potentially layering dough and fat layers together to laminate for a flaky baked product | Pizza crust, Biscuits, Fondant |

| Cutting or Pressing Shapes | Using a set shape to form a dough, could use a cutter, press, or pan | Sugar cookies, Oreos, Tortilla Chips, Potato Chips |

| Extruding | Pressing a dough or batter through a tube with a specifically shaped opening | Pasta, Spritz cookies, Sausage & Hot Dogs |

| Molding | Using a specific 3-D shape to form a coating and/or dough | Candies with fillings such as peanut butter cups and peppermint patties |

| Coating | Adding a layer to the outside of a food; the layer could be made up of dry ingredients, wet ingredients, or a melting coating that will set upon cooling | Cheetos, Peanut Butter Balls, M&Ms |

| Mixing: | ||

| Hydrating | Mixing of ingredients with the main purpose of water hydrating dry ingredients to get functionality from the dry ingredients | Hydrocolloids, Leavening, Gluten Development |

| Shear / High-Speed Mixing / Emulsifying | Mixing of ingredients with the purpose of particle size reduction and/or emulsion formation | Salad Dressings |

| Homogenizing | Processing a liquid under pressure with the goal of particle size reduction to inhibit separation | Milk, Beverages |

| Water Separation: | ||

| Dehydrating | Removal of water from a food, typically slowly using heat and forced air | Fruits & Vegetables |

| Centrifuging | Separation of particles based on density, often a liquid separated from a semi-solid | Fruit Purees |

| Physical Pressure | Using physical pressure to squeeze out free water, often using cheesecloth | Cheese, Vegetables |

| Straining | Using a filter to remove solids from a liquid. The filter size affects the separation and can include cheesecloth and finer filter paper | Apple Cider, Tea, Coffee |

| Physical/Chemical Reactions: | ||

| Fermentation / Enzyme Reaction | Allowing beneficial bacteria, yeast, or enzymes to convert food through controlled breakdown, production of acid, alcohol, and/or carbon dioxide | Sauer Kraut, Yogurt, Yeast Bread, Soy Sauce |

| Protein Coagulation | Adding an enzyme, salt, acid, physical agitation, or heat to cause proteins to change shape and become less soluble | Cheese, Tofu, Egg White Foams, Cooked Eggs, Cooked Meat |

| Heating: | ||

| Cooking | Heating with a direct heat source, often with a liquid present, typically on the stovetop in a conventional kitchen | Soups, Gravies, Pudding |

| Baking | Heating in an oven, typically referring to baked products | Cookies, Brownies, Cake |

| Roasting | Heating in an oven, dry heat method | Chicken, Nuts |

| Frying | Heating in liquid oil for efficient heat transfer | French Fries, Chicken Nuggets, Funnel Cakes |

| Cooling/Freezing: | ||

| Refrigerating | Cooling a food product to under 40 degrees Fahrenheit | Various |

| Freezing | Cooling a food product to ~ 0 degrees Fahrenheit, converting water to ice in the food, speed of freezing affects product quality | Various |

Next think about where the water is added or removed in the system and what ingredients need to be hydrated to function fully in the food (gums, gluten proteins, leavening, protein powders, etc.).

- Is there enough water in the system to hydrate all of the ingredients like in a beverage?

- Is there limited water in the system leading to minimal hydration of ingredients like in cookies (where often the only water is from the water in the eggs)?

- Is it somewhere in between?

- How much sugar and/or salt are in the system? Both pull water more than other ingredients.

- Consider if the water-containing ingredients need to be mixed with the dry ingredients that need the most hydration first. For instance, gums often need to be mixed with water first before being mixed with other ingredients.

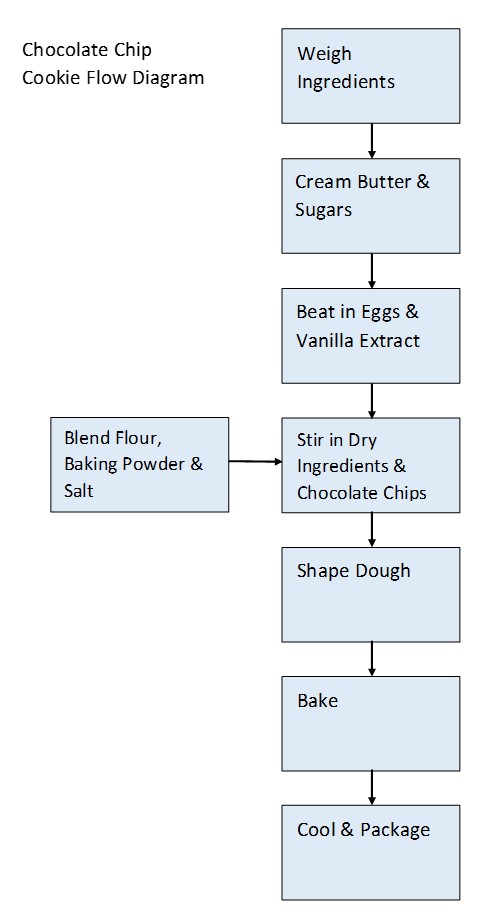

Flow Diagram Starting Point

Once the processing steps have been determined and tested with parameters set (time, temperature, speed, etc.), your team will construct a flow diagram based on the processing steps (not necessarily the equipment). This is helpful as a transition step to processing to determine larger pieces of processing equipment.

As an example, consider the processing steps needed to make a chocolate chip cookie. Here is a typical set of instructions for a chocolate chip cookie recipe modified from Nestle Toll House [1]:

Step 1.

Preheat oven to 375° F.

Step 2.

Combine flour, baking powder, and salt in a small bowl. Beat butter, granulated sugar, and brown sugar in a large mixer bowl until creamy. Beat in eggs and vanilla extract. Gradually add in flour mixture. Stir in chocolate chips. Drop by rounded tablespoon onto ungreased baking sheets.

Step 3.

Bake for 9 to 11 minutes or until golden brown. Cool on baking sheets for 2 minutes; remove to wire racks to cool completely.

Think about the flow diagram that would be constructed from the processing steps for the cookie. Then read through the flow diagram shown below. Do you see how the recipe instructions were converted to a flow diagram? From here, you can construct a flow diagram for your new food product.

- Original NESTLÉ® TOLL HOUSE® Chocolate Chip Cookies. Retrieved January 19, 2021, from https://www.verybestbaking.com/toll-house/recipes/original-nestle-toll-house-chocolate-chip-cookies/ ↵